Solar for Industrial Process Heat Analysis

NREL is developing the first national analysis of the potential for solar technologies to power a wide array of manufacturing applications.

As part of the multiyear Solar for Industrial Process Heat (IPH) project, researchers are evaluating the potential of photovoltaics (PV), solar thermal, and hybrid approaches that produce electricity and/or heat to power a broad range of manufacturing IPH end uses. This analysis will explicitly account for load-reduction potential from energy efficiency measures and load-balancing potential from energy storage technologies.

By developing data sets, tools, and analyses on the integration of solar and manufacturing IPH at both the process and country levels, NREL will enable strategic decision making around this largely unexplored opportunity for solar energy expansion.

Disrupting Business-as-Usual

In the United States, manufacturing IPH is currently dominated by natural gas and coal combustion, a trend that has remained relatively unchanged for several decades.

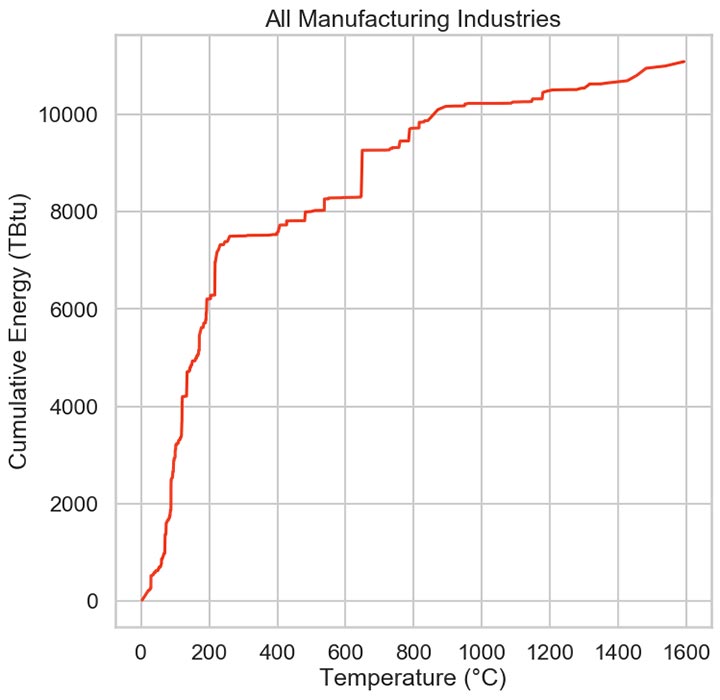

Cumulative process heat demand by temperature in 2014. Illustration by Colin McMillan, NREL Enlarge chart

In fact, fossil fuels provided 90% of reported manufacturing process heat energy in 2014 and 92% in 1992.

The first phase of the solar IPH project has expanded the characterization of energy used for manufacturing process heat in 2014. With this data, it is now possible to identify counties and periods during the year where process heat demand could be met with solar technologies. One new, significant observation is that about two-thirds of process heat is used for applications below 300°C (572°F). The data sets are available for download from the NREL Data Catalog.

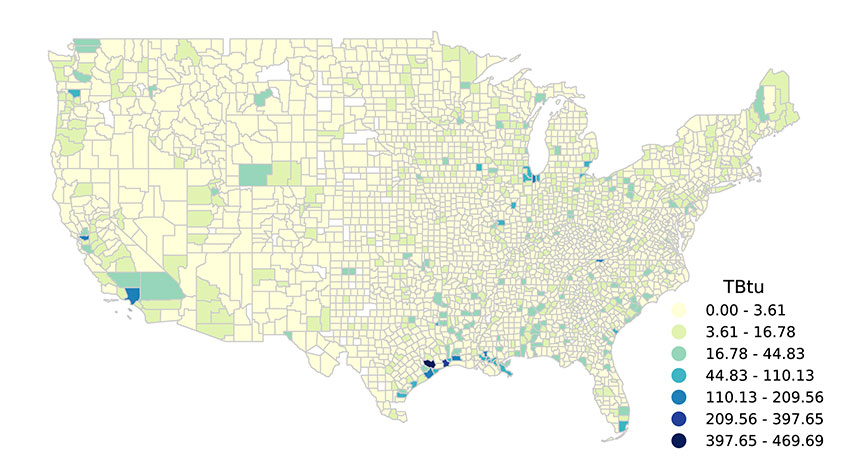

The map below identifies process heat use by county. Counties that have the largest process heat use tend to have high concentrations of energy-intensive industries, such as refining and petrochemicals in Harris County, Texas; pulp and paper mills in Somerset County, Maine; and wet corn milling and ethyl alcohol in Linn County, Iowa.

Researchers have developing analysis capabilities to estimate the technical opportunities for different solar technologies to meet process heat demand based on available land area. Complementary economic analysis is also underway to compare solar technologies with incumbent combustion technologies in a series of case studies.

Featured Publication

Opportunities for Solar Industrial Process Heat

Through the development of higher-resolution data, NREL researchers lay the foundation in this report for continued analysis of opportunities for solar industrial process heat. The new data includes U.S. combustion fuel use for industrial process heat demands and heat load shapes to capture differences in hourly process heat demand based on industry, facility size, and seasonality. Solar plant energy production was then modeled for all counties in the contiguous United States.

Technical Report: Opportunities for Solar Industrial Process Heat in the United States

Data: Report figure data

Interactive Map: Demand and opportunities for solar industrial process heat

Informational Webinar: Recording and presentation slides

Related Publications and Resources

Solar for Industrial Process Heat: A Review of Technologies, Analysis Approaches, and Potential Applications in the United States, Energy (2020)

Using Facility-Level Emissions Data to Estimate the Technical Potential of Alternative Thermal Sources to Meet Industrial Heat Demand, Applied Energy (2019)

The Industry Energy Tool (IET): Documentation, NREL Technical Report (2019)

Generation and Use of Thermal Energy in the U.S. Industrial Sector and Opportunities to Reduce Its Carbon Emissions, NREL Technical Report (2016)

Initial Investigation into the Potential of CSP Industrial Process Heat for the Southwest United States, NREL Technical Report (2015)

Solar Process Heat Basics on NREL.gov

Solar Industrial Process Heat in the News

Zeroing in on the Potential of Solar Energy To Meet Industrial Process Heat Demand, NREL.gov (2021)

Solar Energy Technologies Could Meet Industrial Process Heating Demands, NREL.gov (2020)

Contact

Share

Last Updated April 21, 2025